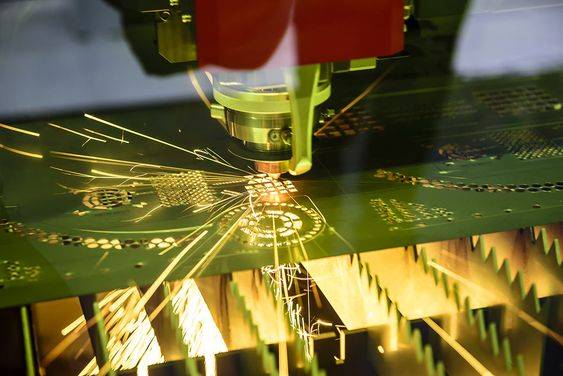

Lasers can produce some of the best cuts for metal fabrication, whether it is a large or small order. But this process is only successful when a fabricator does proper maintenance on the equipment. Without preventive maintenance, lasers are not likely to perform well. That can cause inaccurate cuts, an improperly working machine, and lower quality. Luckily, with good maintenance, fabricators can do well with laser cutting metal.

Checking the Optics

After doing any necessary maintenance on the laser optics, fabricators should ensure that they meet the specifications of the original equipment manufacturer. If the optics do not meet the specs, the beam quality, optics life, and cutting quality are often affected. Fabricators can use beam profilers and analyzers to address the problem. The tools can measure the beam characteristics when the laser passes through. Monitoring the Temperature

The laser depends on the performance of the chiller, so fabricators need to look at the temperature gauge often. If the operating temperature varies too much, the machine may no longer perform as well. When there are extreme temperature changes, there might be resonator damage. That might require time-consuming repairs. There are temperature displays on chillers to better monitor the temperature.

With new technology, companies specializing in laser cutting metal can set a constant temperature, which prevents the need for consistent monitoring.

Keeping the Equipment Clean

One of the more apparent maintenance methods is for fabricators to keep their equipment clean. However, this can get overlooked a lot. Support slats, pallets, and processing areas are common areas to accidentally neglect. However, there can be debris building up in the area, as well as grime and grease. This can affect how the laser cutting metal machine performs. For example, if there is a buildup on the slats, the slat support may no longer work well. That can cause the material to shift during cutting, affecting the accuracy.

Plus, unclean scrap drawers, processing areas, and ducting can be a thermite hazard. This is a mix of oxide from metal and aluminum. The other metal might be a mild steel in a fabricating environment. If the thermite gets ignited, there can be high temperatures that can damage the equipment. Luckily, regular cleaning can help to prevent these and other issues from occurring.

Choose the Best Laser Cutting in Mississauga

Here at Weldflow Metal Products, we take pride in offering the best services in laser cutting in Mississauga for any project that you need. Whether you need components, prototypes, or finished products can do it all. We offer quick cutting processes and can work with a wide variety of materials. If you want to know more, feel free to reach out to us today.

1-866-848-3641

1-866-848-3641 sales@weldflowmetal.com

sales@weldflowmetal.com