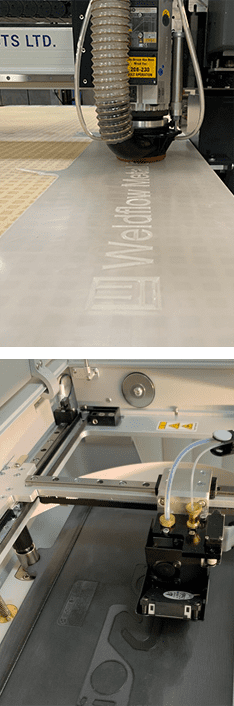

Over the years of working in sheet metal related fabrication services, Weldflow Metal Products felt the need to diversify and expand its scope of CNC router cutting services in other similar areas of manufacturing capabilities. In this regard and considering the present environment, our management team of experts who believes in out of the box thinking has recently expanded the capability and services being offered by purchasing state of the art and highly configurable CNC Industrial Router.

This high-tech equipment offers a remarkable capacity for broadening manufacturing capabilities, reducing time for project completion from small quantities to large batch production. Major reasoning behind this was to enhance Weldflow’s capabilities of processing Custom 3d printing services with such materials as plastics, wood, and Other non-ferrous laminates. This new work center is suitable for one-off, small batch production as well as high volume and high productivity applications in areas of plastic, wood and other non-ferrous materials. The process area of 3d printing companies in Toronto is suitable for sheet size of 60” (5 feet) by 120” (10 feet). It has versatile head and tooling options with seven tool turret center for using 7 different tools in one operational process plus an extra spindle head to accommodate knife system for cutting thin material.

Materials that we can process in sheet form on the CNC router are: Acrylic / Plexiglass, Polycarbonate / Lexan, and PETG. Wood related sheet material like MDF, Plywood, Hardboard, wood veneer, felt material and many more in similar laminate form at 3d printing companies in Toronto can be now processed and routed in different profiles as required.

With the addition of such equipment, our CNC router cutting services have the capability of making sneeze guards for office and retail environment and other custom design. Similarly, we have resources to provide face shields in areas of PPE and other similar gadgets like Utility Hook Tool to avoid touching surfaces and for opening doors, pressing knobs at public places like the elevators, bank tellers etc.

Weldflow Metal Products has also acquired in house 3D printing systems with bank of 3D printers to help in development of prototypes products and scaled down models made from Onyx – Micro Carbon fiber filled nylon and Carbon Fiber – Fiberglass & Kevlar.

Please feel free to contact us for more details.

1-866-848-3641

1-866-848-3641 sales@weldflowmetal.com

sales@weldflowmetal.com