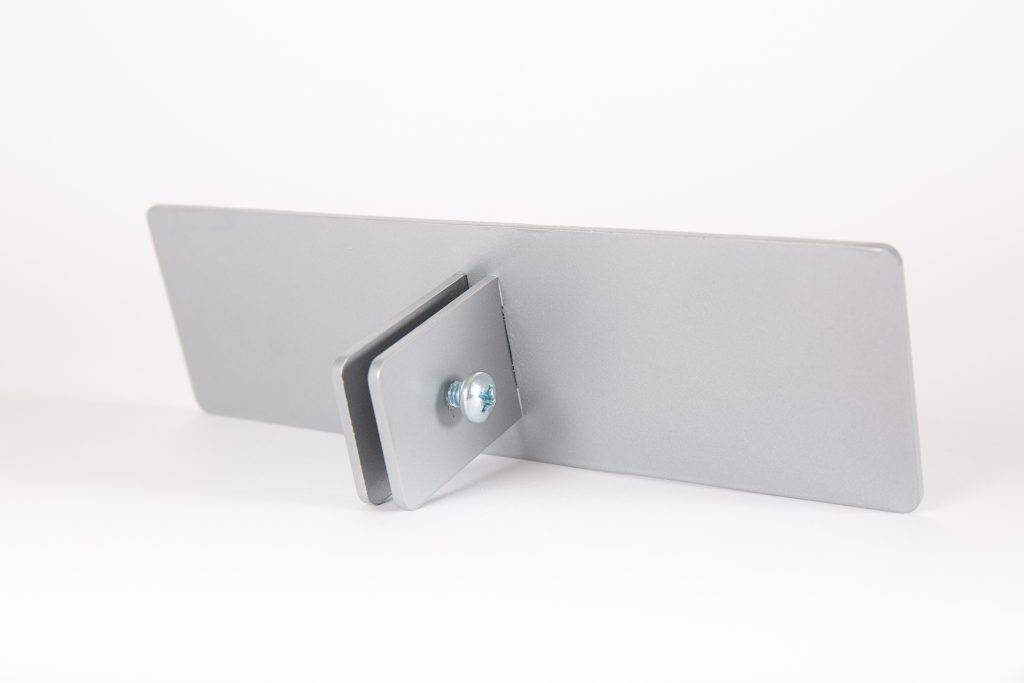

When it comes to steel fabrication, it is essential for companies to follow the right deburring process. Steel often has sharp or rough edges, and that can be a problem. Not only will that cause issues for the plant’s workers, but the edges can also prevent the item from looking its best. The burr might prevent the fabricator from being able to position the steel correctly. Luckily, deburring allows steel fabricators in Toronto to better work with the material.

About Deburring

When a fabricator cuts metal, there could be sharp edges, known as burrs. While newer equipment, such as laser cutting, reduces burring, it does not eliminate the problem completely. So, after the fabricator cuts the piece, they will deburr it through a variety of processes, including power brushing, abrasive blasting, and electropolishing.

Preventing Injuries

Proper deburring avoids injuries as it cleans the sharp edges. If the edges are sharp, anyone who handles them, including workers, clients, and end-users, might get cuts. However, deburring allows everyone to safely handle the material.

Helping the Paint Stick

Once the custom sheet metal fabrication is done, the fabricator or client might paint it. However, if the edges are rough, the paint might not adhere correctly. Instead, the paint might begin to flake off the edges. As a result, the product could undergo corrosion sooner, reducing the life of the product.

Make Your Products More Attractive

A fabricator might need to shape the metal into the correct size and shape for your project. The goal is to make it more attractive, which makes the client more satisfied. However, if there are rough edges, it will not look very good to your clients.

More Protection

When a fabricator is using steel, it is critical that steel be able to stand up to a lot of use. Deburring allows the material to be stronger so it can last longer. Deburring also allows for a smoother finish. Once the steel is clean, it is easier to work with the material. Deburring also stops the part from damaging nearby parts in the finished object.

Removing the Oxide

It is critical that products that steel fabricators in Toronto make do not have oxide. If the steel goes through laser cutting, oxide might build up on the surface. This buildup might prevent a coating from sticking, allowing corrosion to develop. Luckily, the deburring process removes the oxide, as well.

Choose the Best Steel Fabricators in Toronto

Deburring is essential to steel fabrication in Toronto. If you want to learn more about our deburring process, please reach out to Weldflow Metal Products today.

1-866-848-3641

1-866-848-3641 sales@weldflowmetal.com

sales@weldflowmetal.com