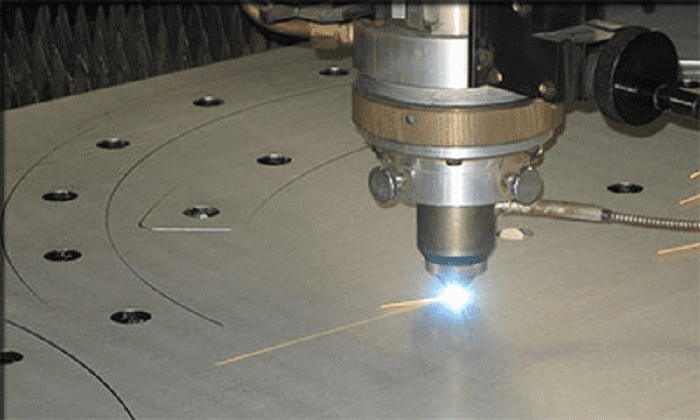

When it comes to laser cutting, it is critical for a fabricator to use the right lasers. But the costs fabricators incur get passed on to you. There are a few factors to consider when it comes to determining the costs of laser metal cutting.

The Cost of Investment

The first factor that affects the cost of laser cutting services is how much the company has invested in the process. This investment includes how many hours they use the tools each year and their uptime. Certain types of cutting systems might cost more, but they also could last longer. Laser companies also need to factor in the cost of consumable items, such as lenses or nozzles.

The Time Required

The next factor is the time spent on your project. If your item takes longer to make, you might end up paying more. That is why you might not want to have the company use a very thick material. The thicker it is, the longer it takes to cut through it, and the more the fabricator will charge you.

The machine is also expensive for the company to run. There is a higher nitrogen consumption with certain types of machines, and if you do not have them use the right material, the quality of the edge might not be very high.

The good news is that cutting machines are becoming more advanced, leading to faster cutting speeds and a better edge quality. Talk to the laser cut metal company to determine the right material for your project, so you get the edge quality you want and can still stay within budget.

The Overhead Cost

One of the biggest factors is the cost of labour. That is essential to helping the company stay open and running. No matter what types of technology they use, the cost of labour is often consistent. Luckily, some of the newest lasers do not take as much time to operate or program. In that case, the savings may get passed on to you.

The Electricity Requirements

Modern machines are more energy-efficient than their older counterparts. Of course, the amount of electricity that a machine uses is only part of what goes into the cost of hiring a laser metal cutting company for your project.

Choose the Best Laser Cutting in Ontario

Companies consider a lot of factors when determining the cost of laser metal cutting services. Knowing more about these factors might help your company save money. Think about the quality of the materials you want them to cut and about how long your order will take to complete. This can give you a rough idea of how much your project will cost. If you want to know more about our services, including pricing, please reach out to Weldflow Metal Products today.

1-866-848-3641

1-866-848-3641 sales@weldflowmetal.com

sales@weldflowmetal.com