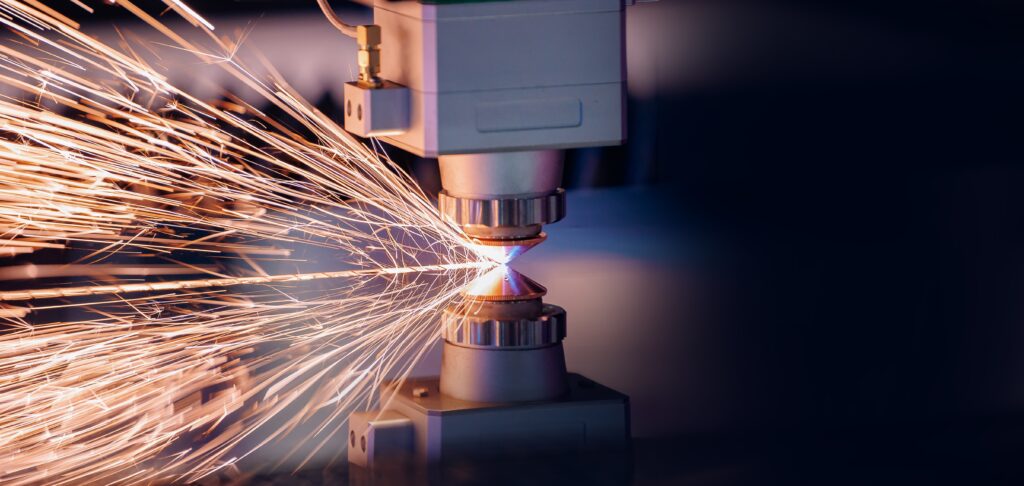

Precision is a critical aspect of laser metal cutting, especially in industries requiring high accuracy for complex designs and components. The ability to achieve clean, precise cuts depends on multiple factors, from laser power settings to material properties. Understanding these elements ensures optimal results for steel laser cutting or working with other metals.

In laser cutting services in Ontario, businesses rely on advanced technology to deliver high-quality fabrications for automotive, aerospace, medical, and industrial applications. To maintain accuracy and efficiency, certain key factors must be considered when performing laser metal cutting.

Laser Power and Beam Quality

The power and quality of the laser beam directly affect the precision of laser metal cutting. Higher power levels allow for deeper penetration, making it easier to cut thicker materials with minimal defects. However, power must be balanced to prevent excessive heat, which can lead to warping or rough edges.

- Higher-wattage lasers handle thicker metals efficiently.

- Beam quality determines edge sharpness and overall cut smoothness.

- Consistent power output ensures uniform results across production batches.

Maintaining the right balance between power and beam focus for steel laser cutting is crucial to achieving fine cuts with minimal material distortion.

Material Type and Thickness

The type and thickness of the material influence how efficiently laser metal cutting can be performed. Different metals react to laser energy in unique ways, affecting the cut’s speed, edge quality, and overall precision.

- Thicker metals require higher laser power and slower cutting speeds.

- Reflective materials like aluminum and copper may require specialized laser sources.

- Steel laser cutting produces optimal results with controlled heat input.

In laser cutting in Ontario, selecting the right laser settings based on material properties helps ensure high-quality cuts with minimal waste.

Cutting Speed and Feed Rate

Proper speed and feed rate adjustments are essential for achieving precision in laser metal cutting. Cutting too fast can lead to incomplete penetration, while cutting too slowly may result in excessive heat buildup and material deformation.

- Higher speeds reduce heat impact but may compromise cut depth.

- Slower speeds provide cleaner cuts but require optimal gas pressure for efficiency.

- Balanced feed rates prevent excessive burr formation on the edges.

Adjusting these parameters according to the specific application ensures efficiency and consistency in steel laser cutting processes.

Gas Type and Pressure

Assist gases play a vital role in laser metal cutting, improving cut quality by expelling molten material and reducing oxidation. The type and pressure of the gas influence the final precision of the cut.

- Oxygen (O₂) is used for carbon steel and enhances cutting speed.

- Nitrogen (N₂) prevents oxidation, ideal for stainless steel and aluminum.

- Argon (Ar) provides a cleaner finish for delicate applications.

Proper gas selection ensures minimal edge roughness and reduces post-processing time for steel laser cutting applications.

Machine Calibration and Maintenance

Even with the best settings and materials, laser metal cutting precision depends on proper machine calibration and regular maintenance. A well-maintained machine ensures consistent performance and extends its lifespan.

- Laser alignment is necessary for maintaining accurate beam focus.

- Regular lens and mirror cleaning prevents beam distortion.

- Software updates enhance cutting efficiency and precision control.

For businesses relying on laser cutting in Ontario, investing in routine maintenance ensures optimal machine performance and precision across all cutting projects.

Ensuring Precision with Advanced Laser Metal Cutting

Achieving high precision in laser metal cutting requires attention to laser power, material properties, speed settings, assist gas selection, and machine upkeep. Each factor ensures clean, accurate cuts while minimizing waste and rework.

Weldflow Metal Products specializes in steel and advanced laser cutting in Ontario, delivering high-precision solutions tailored to industrial and commercial applications. Contact Weldflow Metal Products today for high-quality laser cutting services.

Also read:

Sharpening Innovation: Laser Metal Cutting in Product Development

How Laser Cutting Technology Has Revolutionized Modern Industries

1-866-848-3641

1-866-848-3641 sales@weldflowmetal.com

sales@weldflowmetal.com